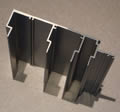

Aluminum Extrusion

Aluminum extrusion refers to aluminum material coming with different sectional shapes, and it can be achieved by hot melting and extruding aluminum bars. It is characterized by high strength, high corrosion resistance, simple assembly, and good durability, etc.

The Production Process of Aluminum Extrusion

There are three main procedures in the process, namely casting, extrusion and coloring. The process of coloring mainly involves the steps of oxidation, electrophoretic painting, fluorocarbon spraying, powder spraying, wood grain transfer, etc.

1. Casting is the first procedure of aluminum extrusion production.

(1) Dosing: Raw materials are reasonably mixed with appropriate amounts of alloy elements in accordance with the particular alloy to be produced.

(2) Melting: Pour the well-mixed raw materials into the melting pot and then remove the slag and gas in the melt through degassing, deslagging and refining.

(3) Casting: The melted aluminum liquid will, through a deep well casting system, be cast into round casting rods with different specifications after cooling.

2. Extrusion. The aluminum extrusion is shaped through extrusion.

First, moulds are made according to the sectional design of the products. Second, the heated round casting rods are extruded into different shapes from the moulds by an extruder. Different alloys have different levels of heat treatment. For instance, the strengthening of heat treatment of the aluminum alloy 6063 is completed through and air blast quenching and then artificial aging.

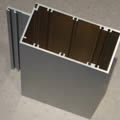

3. Coloring. Here the coloring mainly refers to the process of oxidation.

Oxidation

The surface of aluminum extrusion is not well enough in terms of corrosion resistance. So it needs to be anodized to enhance its corrosion resistance, abrasive resistance and surface artistry.

The Main Steps

(1) Surface pretreatment

In order to get a complete and compact artificial oxidation film, the aluminum extrusion needs to be cleaned with physical or chemical methods. Mirror surface and matte surface can be obtained through mechanical methods too.

(2) Anodization

A layer of film AL203 will come into being after the anodization of the surface under certain technological conditions. The film is compact and porous with strong absorption.

(3) Sealing

The porous oxidation film should be sealed off to be protected aluminum extrusions from pollution. This can also enhance the corrosion resistance and abrasive resistance of the film. Due to its strong absorption before sealed off, the transparent oxidation film can absorb some metal salts from the film holes which will enable the aluminum extrusion to show many colors apart from silver, such as black, bronze, golden and the color of stainless steel.

Maintenance

1. The aluminum extrusion should be moved gently to avoid surface bumps which will affect the artistry.

2. Should be covered with tarpaulin to avoid being affected by rainwater and snow in transportation.

3. The aluminum extrusion should be kept in dry environment where there is plenty of light and better ventilation. Meanwhile, rain, water and snow should be kept out.

4. When stored, the aluminium extrusion should be kept more than 10CM above the ground with a piece of wood under its bottom.

5. Must not be kept together with chemical materials or moist materials.

6. When installed, the aluminum extrusion should be taped with waterproof tape. The frame against the wall should be made from quality cement and sandy soil so as to keep the oxidation film and painting film from being attainted.

7. After being processed into doors and windows, the aluminum extrusion should be cleaned regularly with a clean cloth and neutral detergent.

Packing of aluminium extrusion

Usually, the protective film should be first pasted, then EPE and covered with kraft paper which can help avoid being scuffed or damaged. After being tied up and outer packing, the aluminum extrusion can be packed into boxes. Most of the exported products should be loaded into containers. So the length of containers should be taken into account when packing. And generally, the length of a container is 12M.

Our company is a major manufacturer and supplier of standard aluminum extrusion in China. To ensure the quality of products, our company has adopted advanced production technologies and hired professional engineers and technicians. Our solar panel frame, construction aluminum profile, etc. have gained widespread recognition thus earning certification of the ISO9001:2000 international quality system and ISO14001:2004 international environment management system. As a result, our market continues to expand with our products exported to over 40 countries and regions such as Japan, Indonesia, Australia, Algeria, Canada, Holland, Britain and Germany. If you are interested in our products, please do not hesitate to contact us. We are looking forward to being at your service.